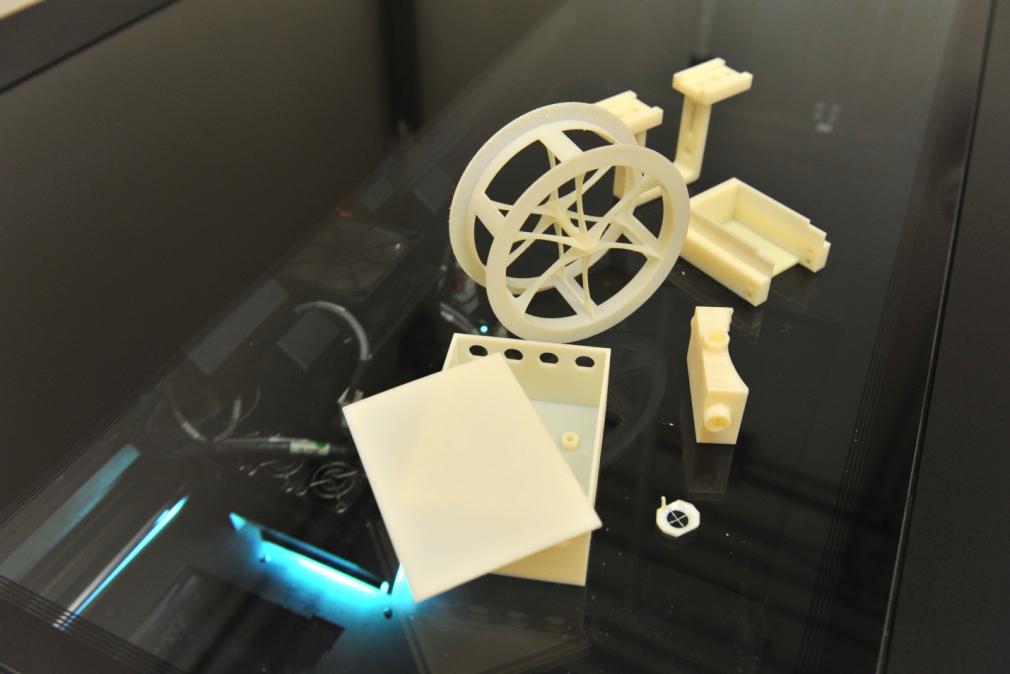

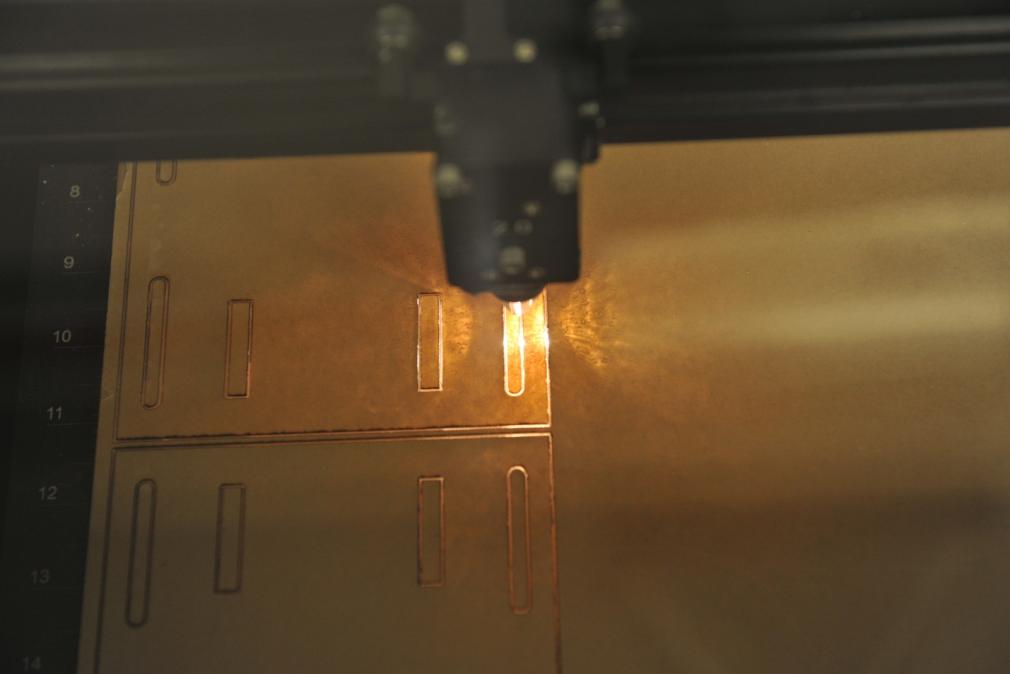

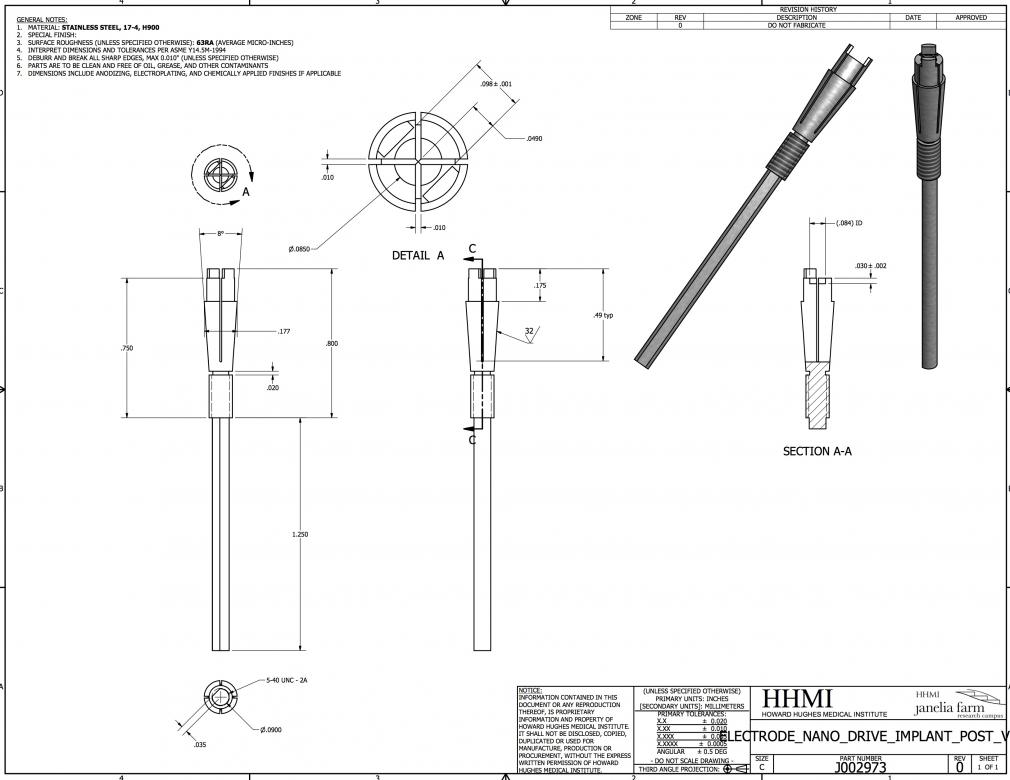

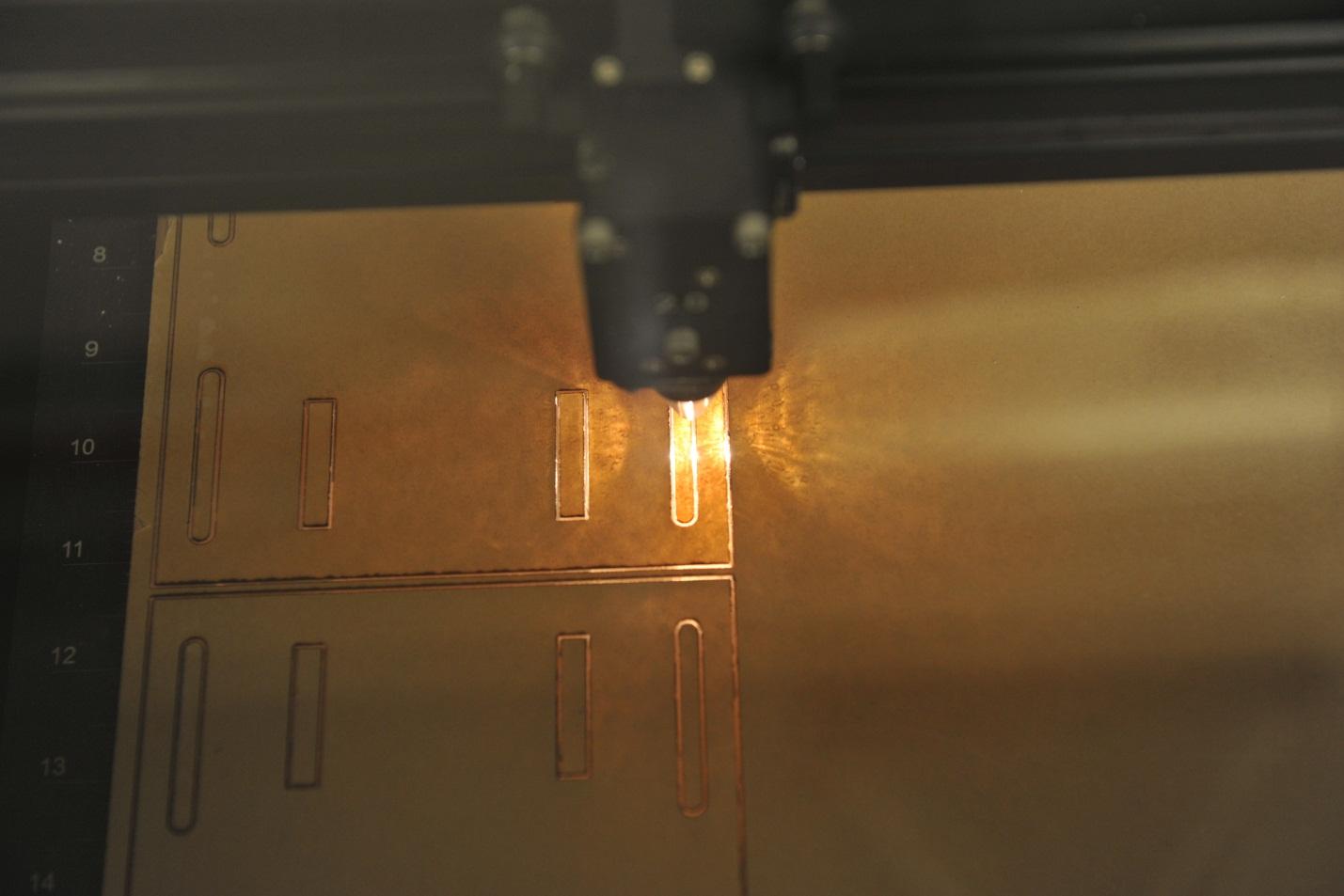

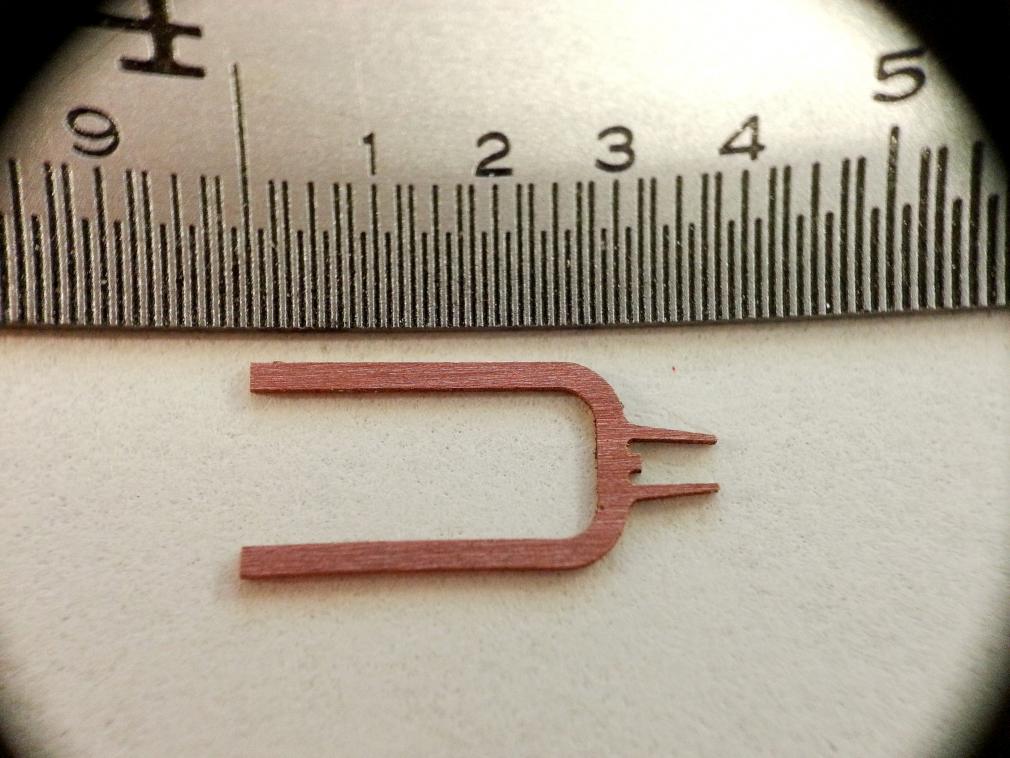

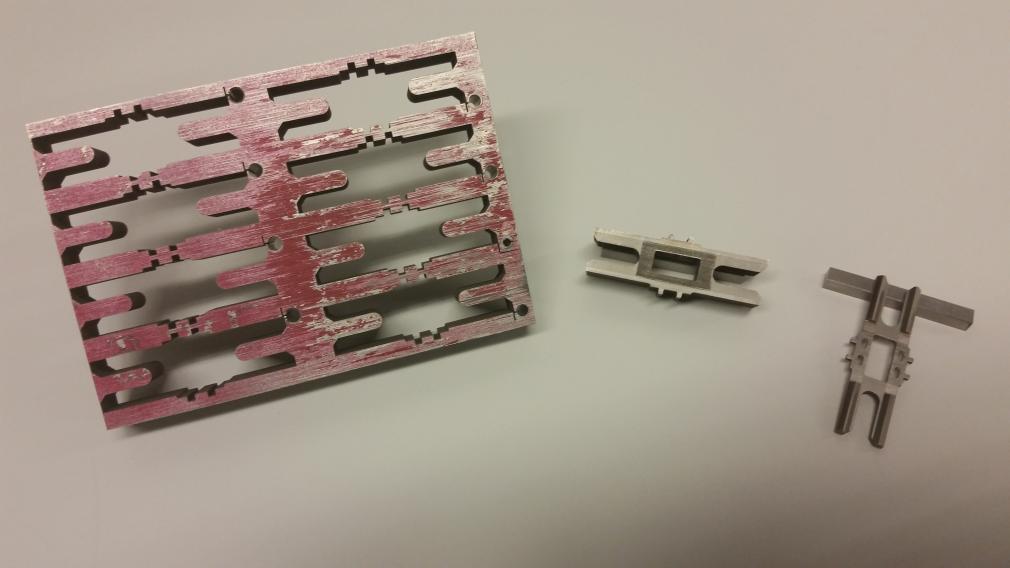

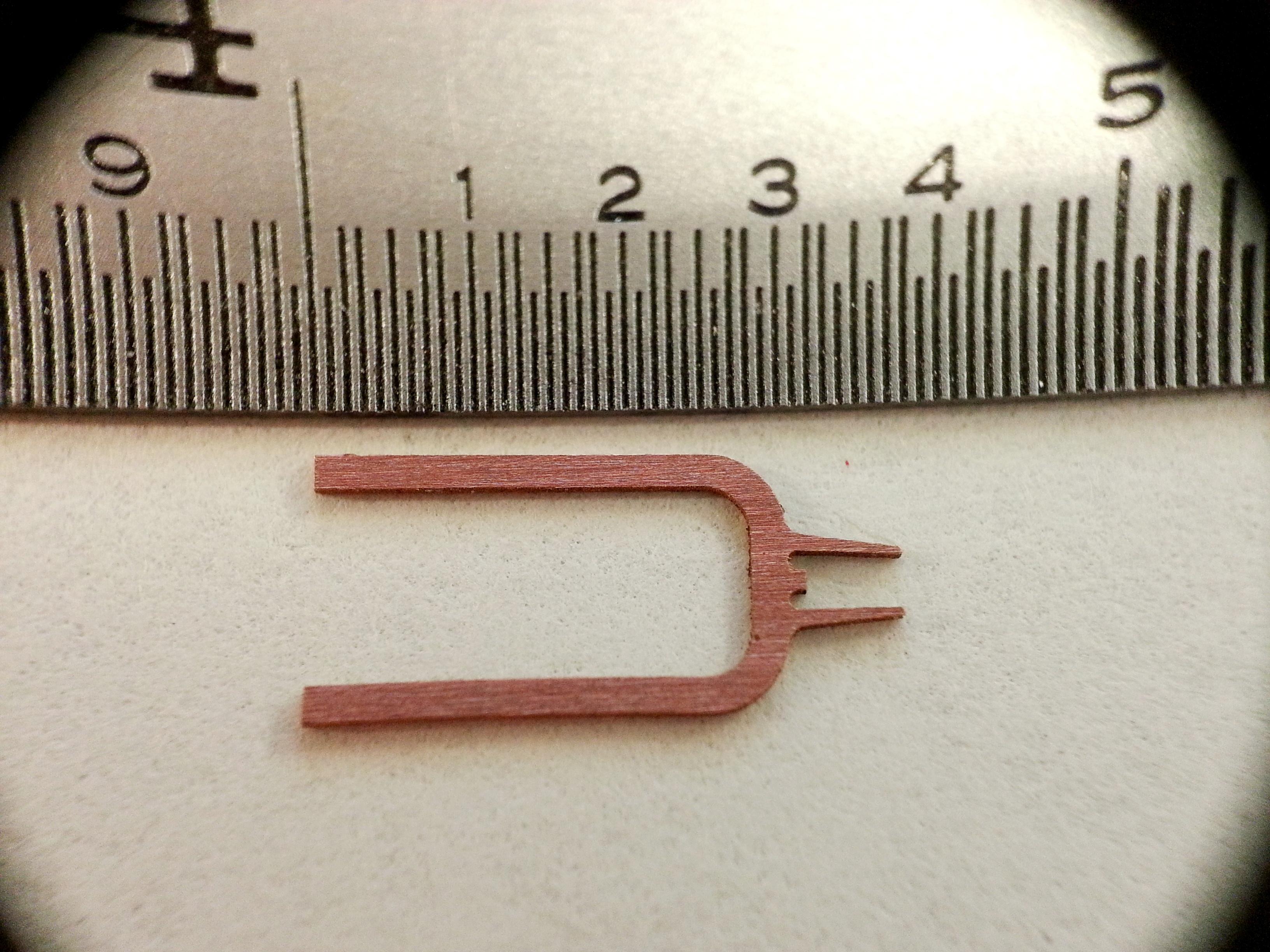

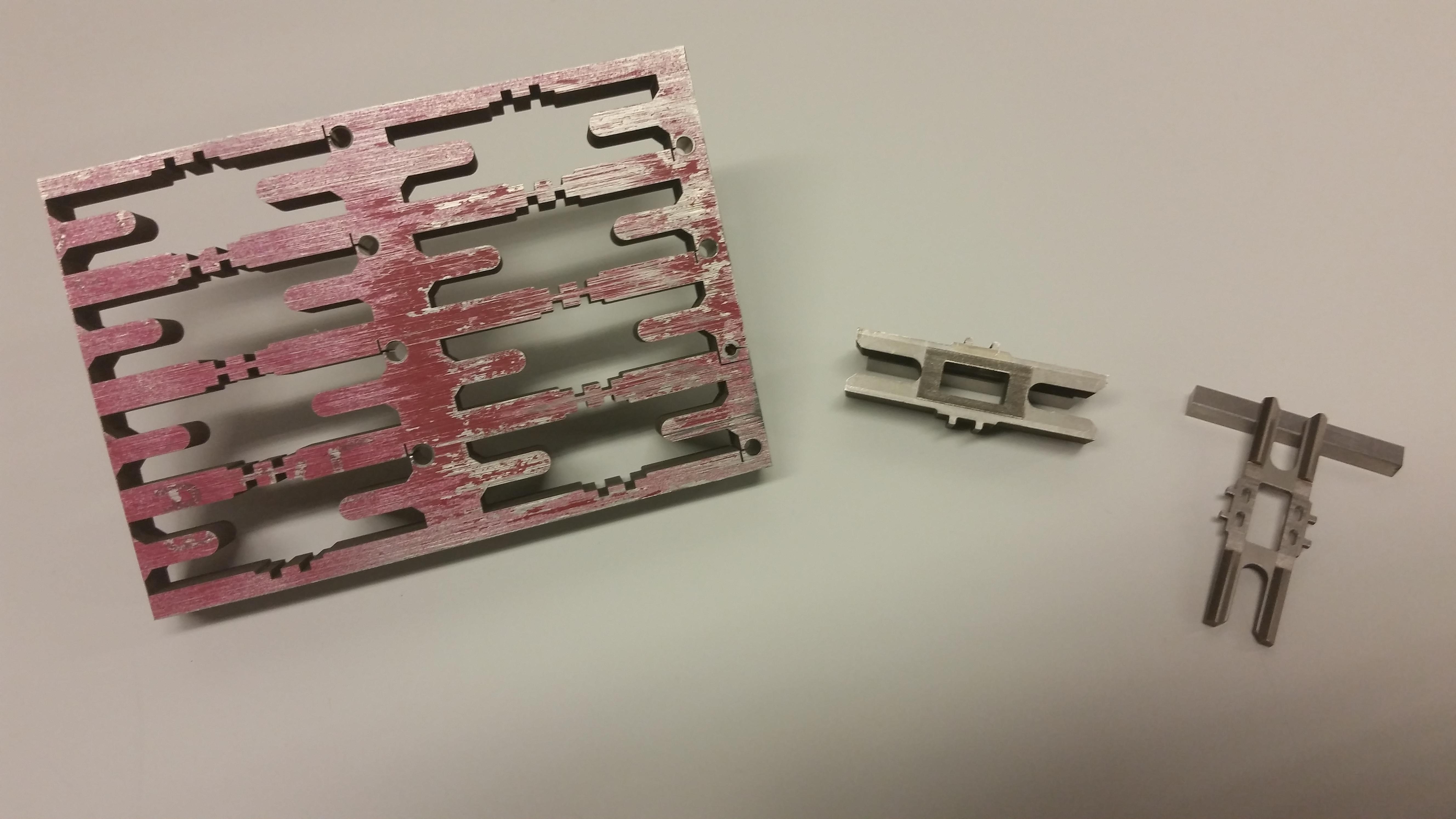

Janelia Experimental Technology's services include machining and fabrication with a team of experienced scientific machinists to provide high precision, rapid response, in-house fabrication to Janelia and visiting researchers. In-house fabrication at Janelia is performed at jET’s machine and fabrication shop which utilizes enhanced computer numerical control (CNC) machinery, wire electrical discharge machining (EDM), and 3D printing capabilities for rapid prototyping. Janelia Experimental Technology scientific machinists work closely with Janelia and visiting researchers in a collaborative manner for many types of projects including rapid part creation, modifications to existing parts or off-the-shelf components, and high precision fabrication that require specialized techniques.

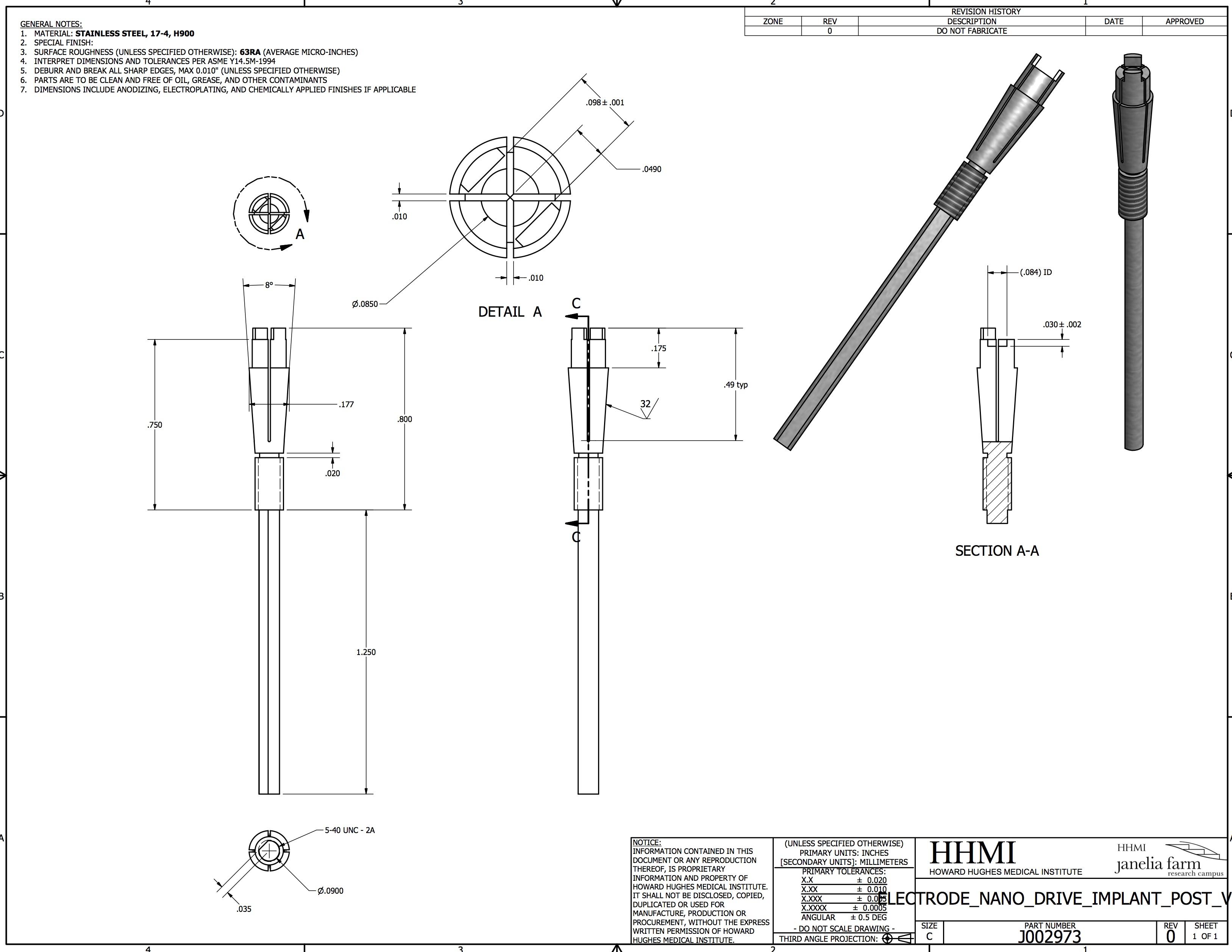

Additionally, jET maintains a selection of close vendors that are called upon to extend its capabilities and fabrication throughput. For outsourced parts, jET provides technical management in the form of initial consultation with the researchers, part drawing creation, vendor quoting, technical oversight, and inspection on received parts. These services refine the researchers' thoughts and visions into custom parts that can be manufactured to further their research.

Janelia Experimental Technology also supports a satellite machine and fabrication shop that is operated by and for the researchers themselves, after they complete a short training course. This "self-service" capability speeds up many smaller tasks.